MANUFACTURING CAPABILITIES

MANUFACTURING CAPABILITIES

Global Manufacturing Solutions & Precision Welding Services

At Newman Technology, our manufacturing capabilities are built to support precision, scalability, and innovation at every stage of production. From metal forming and welding to plastic molding and automated assembly, we combine advanced equipment with skilled expertise to deliver high-quality components for the automotive industry.

The Full Scope of Our Expertise

Our in-house Research & Development team collaborates closely with customers to drive innovation from concept through production. We provide full product development support, including prototyping, feasibility studies, and design optimization to meet cost, performance, and manufacturing goals.

Advanced automation is integrated across our facilities to enhance consistency, efficiency, and throughput. From robotic assembly and material handling to automated inspection systems, we engineer intelligent processes that reduce cycle time and support scalable production.

offers a broad range of advanced welding processes to meet the structural, cosmetic, and performance requirements of today’s automotive components. Our welding capabilities include MIG, TIG, Laser, Spot, and Projection Welding, selected based on material type, joint design, and end-use function. Supported by precision fixturing and process controls, our welding systems deliver consistent, high-strength joints that meet ISO/IATF standards.

Our in-house stamping operations range from 80T all the way up through 4,000 press capabilities. We produce highly accurate stampings utilizing Progressive, Transfer, & Tandem Press machines. All press operations employ automated and robotic feed systems, as well as quick die change systems to maximize production efficiency. On-site CAD/CAM technology allows our engineers to design and manufacture custom stamping dies quickly and efficiently.

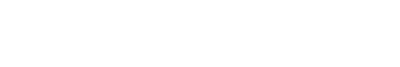

Our roll forming capabilities enable the continuous shaping of long, uniform metal profiles with high strength and tight tolerances. This process is ideal for producing lightweight structural components used in automotive applications.

Our tube mill operations focus on the production of custom-formed tubing used in structural and exhaust-related components. These high-quality tubes are created through precision seam welding, sizing, and cutting—all performed in a tightly controlled environment. Inline monitoring systems ensure uniform wall thickness, roundness, and weld integrity throughout the process. Additional capabilities such as surface treatments and end-forming allow us to deliver ready-to-assemble tube solutions tailored to exact customer requirements.

Our tube bending and forming systems are engineered for high precision and repeatability across a wide range of tube sizes and geometries. Using multi-stack tooling and programmable control, we produce complex bends and end forms without compromising wall integrity or dimensional accuracy. These capabilities are essential for applications like fluid and exhaust routing, where precise fit and performance are critical. Integration with upstream and downstream processes ensures smooth flow through production.

Injection molding is a manufacturing process used to produce complex plastic components with high precision and repeatability. It involves injecting molten plastic into custom molds to create parts that meet exact specifications and strict quality standards. This process is widely used in automotive applications for producing interior trims, clips, housings, and other durable plastic components.

Our low and high gloss extrusion lines are capable of producing complex, multi-material profiles with precise surface finishes and consistent dimensions. Co-extrusion capabilities enable the combination of rigid and flexible materials in a single profile, while downstream processing—including cutting, punching, and packaging—ensures the final part is production-ready. Quality control systems monitor color, gloss, and profile shape throughout the run.

Stretch bending operations allow us to form curved aluminum and steel profiles with high precision and smooth surface finishes. This process applies controlled tension and force to the material during forming, minimizing wrinkling and spring-back for a clean, consistent shape. Used primarily for trim and structural components, stretch bending supports complex geometries and tight tolerances that are difficult to achieve through other methods.

We offer comprehensive finishing services including electrocoat (e-coat) and topcoat paint systems designed for maximum corrosion protection and surface appearance. E-coating ensures uniform coverage, even in complex or recessed geometries, while our paint lines apply durable finishes in accordance with customer requirements.

Our hydroforming systems are tightly controlled to ensure dimensional accuracy and repeatability. Using high-pressure hydraulic fluid, we shape metal tubes into detailed forms within a die cavity, eliminating the need for welded joints or multiple sub-assemblies. This process allows for weight reduction and improved structural performance, making it ideal for chassis and crash energy management components.

Wire braiding is used to add structural strength to automotive exhaust applications. High-speed braiding machines apply consistent tension and coverage, resulting in uniform braid density and high mechanical strength.

We offer automated adhesive application systems to support bonding, gasketing, and vibration damping applications. Precision-controlled dispensing equipment ensures consistent bead size, placement, and cure, reducing material waste and improving assembly efficiency. These processes are critical in meeting automotive sealing and structural integrity standards.

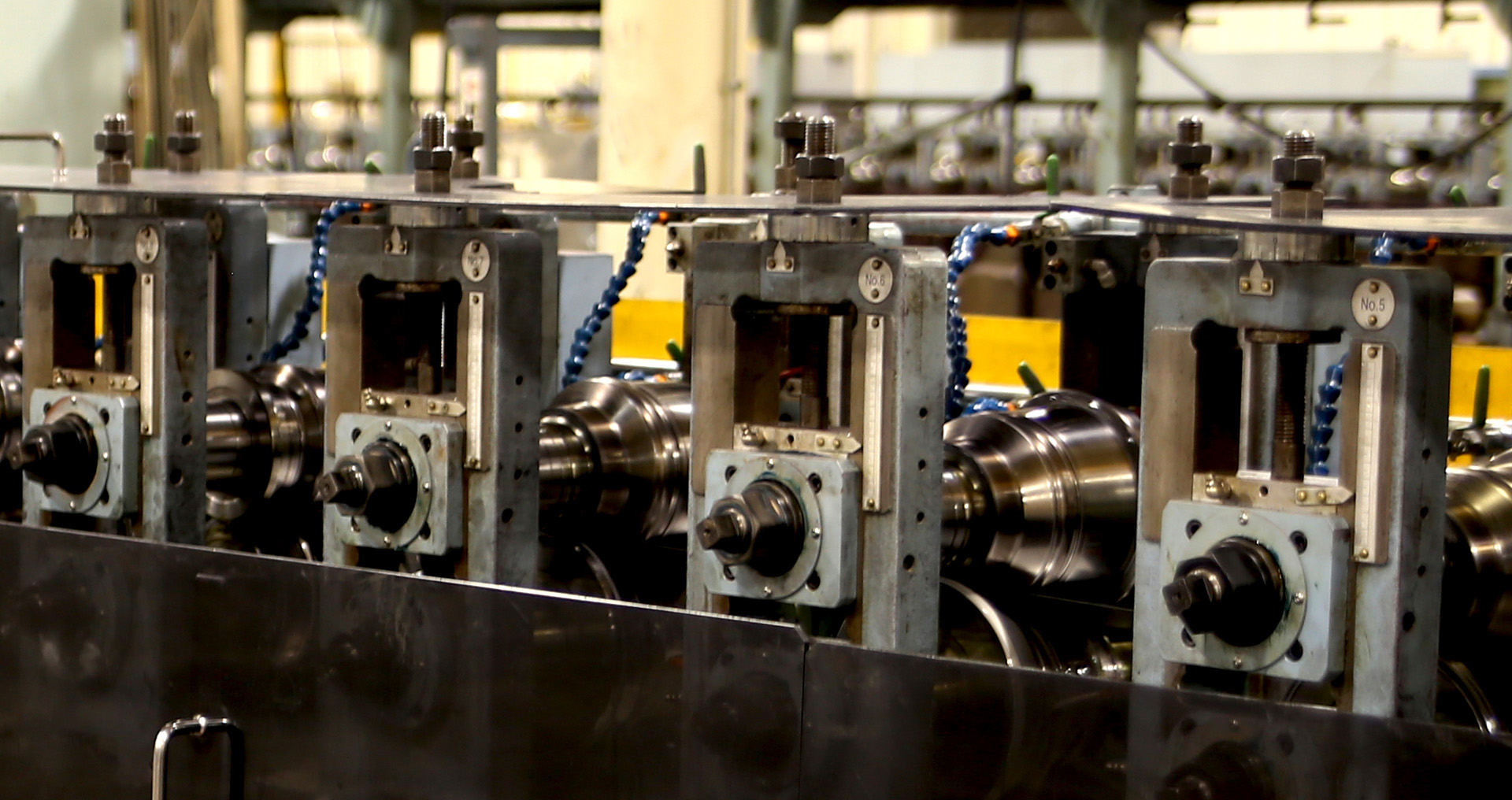

Our quality assurance program includes comprehensive conformance testing to validate the performance and dimensional accuracy of each part. Leak testing systems ensure air- and fluid-tight assemblies, while LMI systems provide non-contact dimensional checks against CAD models. Additional in-line and off-line tests, including functional checks and material verification, ensure every part meets or exceeds customer and regulatory standards.

Our multi-stage part washing systems are designed to remove oils, particles, and other contaminants prior to assembly, painting, or shipment. These systems include ultrasonic agitation, high-pressure spray, and drying zones, all configured to meet strict cleanliness specifications.

Committed to Quality at Every Step

At Newman Technology, quality isn’t a final checkpoint—it’s built into every stage of production. Our robust quality assurance systems ensure every component meets the highest standards of safety, precision, and performance.

NEWMAN TECHNOLOGY

Partner with a Leader in Automotive Innovation

Discover how our commitment to quality, innovation, and customer focus sets us apart. Let us help move your business forward with proven performance and precision.