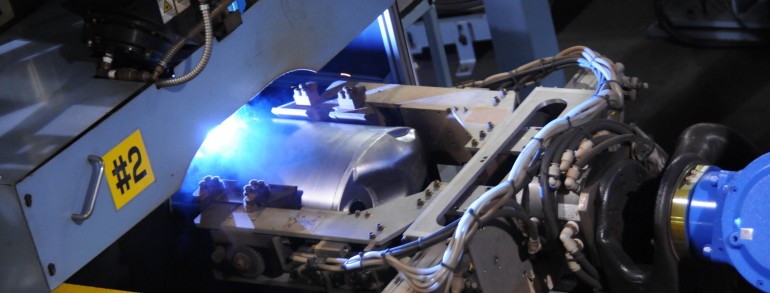

Our Rafted Rollforming and in-line co-extrusion processes yield complex cross section configurations and high quality trim with a variety of finishes. [button text="Read More About Our Rollforming & Co-Extrusion Technology" link="https://www.newmantech.com/technology/rollforming-coextrusion" style="default" size="normal" target="_self" display="inline" icon="no"]

Read more

Rollforming & Co-Extrusion