Rollforming & Extrusion Technologies

Rollforming & Extrusion Technologies

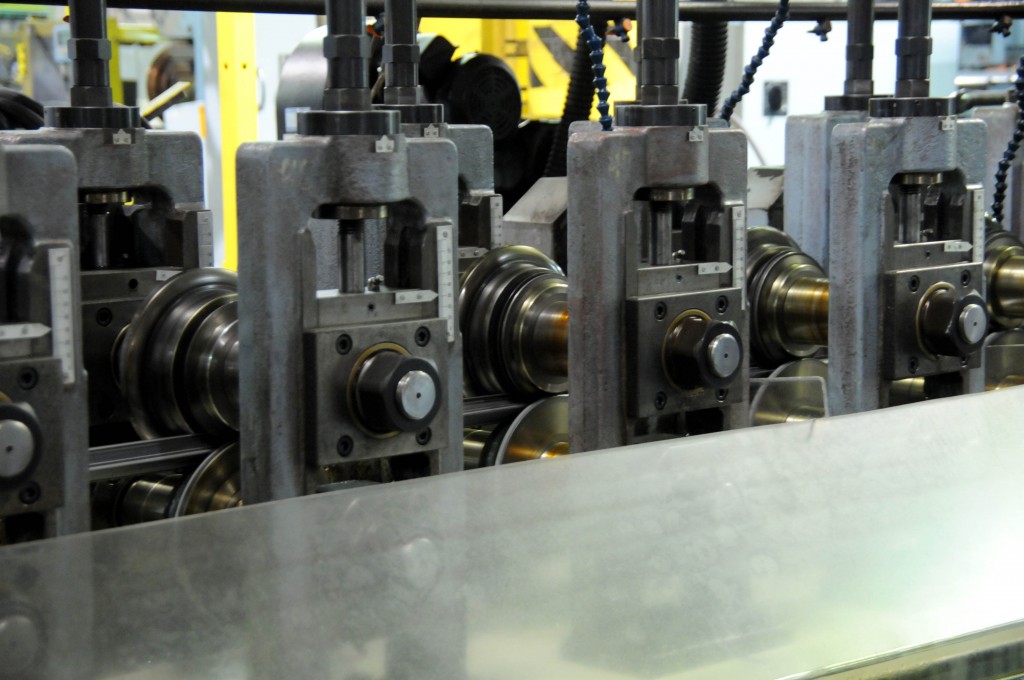

Our Rafted Rollforming lines use up to 60 roll dies to create complex cross section configurations with Class A surfaces. Continuous in-line welding and cutting yields high strength and cost effective efficiencies. Integrated custom fabricated stretch bending machines and notching presses allow for a smooth production flow from raw material thorough final fabrication. Our in-line co-extrusion and cutting processes, along with our flocking application allow us a continuous production process yielding high quality trim with a variety of finishes.